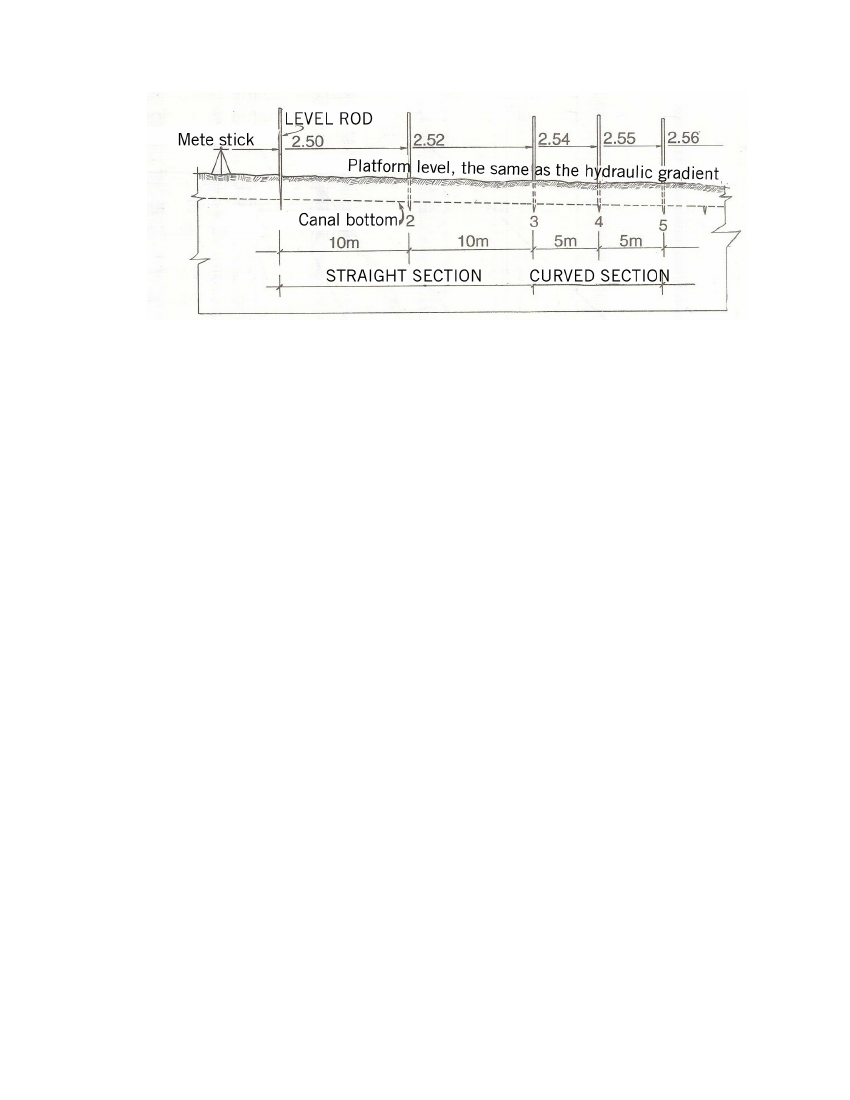

Slope: 2/1000 (two per thousand), which means that every

10 m horizontally there is a difference in elevation of 2 cm and every

5m horizontally there is a difference in elevation of 1 cm.

Fig. 12

Lining the Canal

This consists of placing a layer of concrete (Concrete compressive strength, f'c:

175 kg/cm2) on the bottom and side walls of the canal, forming a uniform

thickness and a polished finish. Level the finished work to the thickness

determined by the wooden frame.

Procedure:

a) Fill with rubble every 10m on a straight section and every 5m or so

on a curved section, taking the design slope into account.

Use a mete stick to achieve more precision.

b) Fitting the wooden frames. The guide frames or master frames will

be placed in each template, properly aligned, squared and plumbed

with respect to the centre line of the canal, fixing them with stakes

and No. 16 wire hammered into both banks. Subsequently, the

construction worker will fit intermediate wooden frames every 2.50m

in straight sections, checking the required slope with a level hose.

(0.5cm difference in elevation). Each one will be aligned, squared, plumbed

and fixed.

11